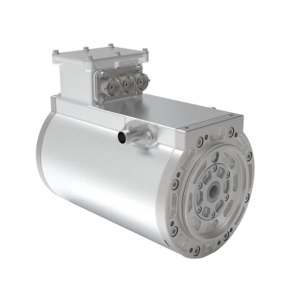

A noticeable shift has occurred in global industrial procurement, with an increasing number of engineering and purchasing teams turning to Chinese partners for their PMSM motor supply. This trend extends beyond basic cost calculations. It reflects a strategic alignment with manufacturing ecosystems that offer distinct advantages in integrated supply chains, responsive engineering, and scalable production. As a Chinese PMSM motor manufacturer, we at Santroll have observed this evolution firsthand. The preference stems from a combination of structural, technical, and commercial factors that directly impact a buyer’s project viability and long-term operational stability.

Concentrated Supply Chain and Manufacturing Ecosystems

The decision to source a PMSM motor often involves securing related components like drives, controllers, and precision gears. China’s established industrial regions host deeply concentrated ecosystems for electromagnetic materials, precision machining, and electronics. Partnering with a Chinese PMSM motor manufacturer provides streamlined access to this vertical integration. This reduces logistical complexity, minimizes lead times caused by multi-country sourcing, and simplifies quality oversight. For a global buyer, this ecosystem cohesion translates into greater supply chain resilience and faster time-to-market for their own products, as the entire motion solution can be developed and coordinated from a single industrial hub.

Agile Adaptation to Specific Technical Requirements

Standard catalog products frequently fail to meet the precise torque, form factor, or environmental specifications required for specialized applications. Chinese PMSM motor manufacturers have cultivated a capacity for agile engineering and rapid prototyping. This flexibility allows for direct collaboration on customizations—whether modifying flange designs, integrating specific feedback devices, or tailoring winding parameters for unique voltage ranges. This collaborative, solution-oriented approach is a practical advantage. It enables buyers to obtain a PMSM motor that functions as a designed component within their system, rather than forcing a design compromise around a standard, off-the-shelf unit.

Empirical Validation and Cost-to-Performance Rationalization

The operational history of Chinese manufacturing in this sector now includes extensive empirical validation. A significant volume of PMSM motors from China are deployed globally in demanding fields like automated logistics, packaging machinery, and renewable energy systems. This track record provides tangible, field-tested data on reliability and performance. When combined with a competitive cost structure, it creates a compelling cost-to-performance ratio. The economic advantage is not merely about lower initial price but about achieving the required performance, durability, and service life at a total cost of ownership that maintains project budgets. Our focus at Santroll is on refining this equation through material science and control integration.

The growing preference for a Chinese PMSM motor manufacturer is a calculated response to modern manufacturing demands. It aligns buyer needs for supply chain coherence, technical adaptability, and economic efficiency with the capabilities now consistently demonstrated within China’s industrial sector. This partnership model moves past transactional purchasing toward collaborative development. For procurement teams, the value is clear: it reduces systemic risk and enhances product capability. The operational evidence supporting this shift continues to accumulate, reinforcing the logic behind the sourcing decision.