When we at Santroll consider electric motor solutions for marine environments, the focus always lies on efficiency, durability, and adaptability. Electric motors in maritime settings face unique challenges, including exposure to harsh weather, varying load conditions, and long operational cycles. Therefore, understanding the critical features of permanent magnet synchronous motors (PMSMs) is essential for companies seeking reliable propulsion systems.

High Torque Density for Compact Design

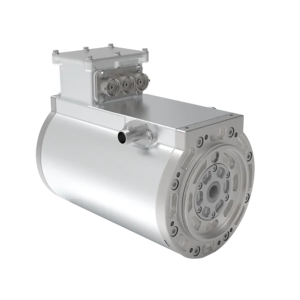

One essential feature of PMSMs for marine use is high torque density. Electric motors on vessels must deliver powerful performance while occupying limited space. At Santroll, we prioritize PMSMs that provide significant torque relative to their size, enabling smaller, lighter propulsion units. This is particularly valuable for applications such as yachts, ferries, or auxiliary propulsion systems where deck space is at a premium. By optimizing the electromagnetic design and leveraging high-performance permanent magnets, electric motors can achieve this high torque density without compromising efficiency.

Thermal Management for Continuous Operation

Another critical consideration is thermal management. Marine environments often impose continuous or heavy-duty operation on electric motors. Without effective cooling strategies, motors may overheat, reducing performance or causing long-term damage. At Santroll, we evaluate PMSMs that feature advanced thermal regulation techniques, such as liquid cooling or optimized heat-dissipating housings. Proper thermal management ensures that electric motors maintain stable performance under sustained loads, which is vital for vessels operating in open water where service interruptions can be costly.

Corrosion Resistance and Material Integrity

The marine environment is inherently corrosive, making material selection a major factor for PMSMs. Electric motors must resist saltwater intrusion and moisture exposure over long periods. At Santroll, we emphasize electric motors constructed with corrosion-resistant coatings, stainless steel components, and protective seals. These features extend operational life and reduce maintenance intervals, a critical aspect for commercial marine operations. In addition, the structural integrity of the motor housing ensures that the electric motor can withstand the mechanical stresses associated with waves and vibrations.

Reliability and Maintenance Considerations

Beyond physical attributes, the overall reliability of PMSMs plays a decisive role in marine applications. Electric motors that offer low maintenance requirements and predictable performance are more appealing to marine operators who value uptime. At Santroll, we analyze factors such as bearing selection, winding insulation quality, and sensor accuracy when recommending PMSMs for marine propulsion. These practical considerations help ensure that electric motors continue to function efficiently throughout their service life, minimizing operational disruptions.

Santroll believes that selecting PMSMs with the right combination of torque density, thermal management, corrosion resistance, and reliability is crucial for any marine application. By focusing on these features, businesses can ensure that their electric motors deliver consistent, efficient performance while withstanding the demanding conditions of marine environments. This approach not only supports operational efficiency but also contributes to the long-term sustainability of electric propulsion in maritime industries.