For professionals in industries reliant on precision motion, the components inside an electric motor matter a great deal. At Santroll, we focus on the engineering behind every part, and the armature stands as a central element in many motor designs. Grasping its function is not just academic; it directly influences performance specifications, maintenance schedules, and application suitability. This examination outlines what an armature is, how it operates, and its practical significance for your operations.

Defining the Armature’s Core Purpose

In a simplified sense, the armature is the rotating component of a DC electric motor or the stationary component (stator) in many AC alternatives, though it is most commonly associated with the rotor in DC systems. Its primary role is to interact with the magnetic field to produce torque. The armature carries the current that is meant to be manipulated by the magnetic field, making it the active part where energy conversion happens. Within an electric motor, the armature is the workhorse that translates electrical energy into the mechanical force that drives your machinery. The efficiency of this entire process hinges on the armature’s design and integrity.

The Physical Construction and Key Components

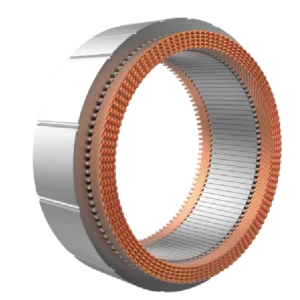

An armature is not a single piece of metal; it is a carefully assembled structure. It typically consists of a laminated silicon steel core, a set of copper windings, and a commutator. The laminated core reduces energy losses from eddy currents, a consideration we at Santroll prioritize for thermal management. The copper windings, or coils, are laid into the slots of the core. When current passes through these windings, they become electromagnets. The commutator is a critical mechanical switch attached to the shaft. It maintains the correct direction of current flow through the armature windings as it spins, ensuring continuous rotation in a single direction. This precise arrangement is what allows a standard electric motor to provide consistent, usable power.

Operational Principles: Electromagnetism in Action

The operation of an armature is a direct application of electromagnetism. When electrical power is supplied to the motor, it creates a magnetic field in the stator. Simultaneously, current flows into the armature windings via the commutator and brushes, turning the armature into an electromagnet. The fundamental principle is that like magnetic poles repel and unlike poles attract. The magnetic field from the stator exerts a force on the magnetic field of the armature, causing it to rotate. The commutator’s role is crucial here; it systematically reverses the direction of the current in the armature windings at the exact moment needed to keep the rotational force, or torque, constant. This continuous interaction is what makes the shaft of the electric motor spin and deliver power to the load.

The reliability of any electric motor is intrinsically linked to the quality of its armature. From the grade of lamination steel to the precision of the commutator, each detail affects performance, lifespan, and thermal characteristics. We engineer our components with these factors in mind, ensuring that the core mechanics of the electric motors meet the demanding requirements of industrial applications. A thorough grasp of the armature provides a solid foundation for specifying, maintaining, and troubleshooting the motors that power your critical systems.