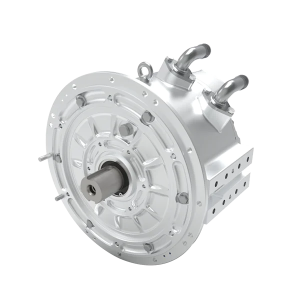

In industrial automation, the selection of a prime mover directly influences system efficiency, control fidelity, and operational cost. A Permanent Magnet Synchronous Motor (PMSM) represents a significant evolution in electromechanical design. At Santroll, we utilize PMSM motor technology as the core of our high-end servo systems. This article will define the operational principle of a Permanent Magnet Synchronous Motor and examine the empirical advantages it holds over traditional induction and brushed DC motors in precision applications.

Operational Principle: Synchronous Rotation and Permanent Magnet Flux

The defining characteristic of a Permanent Magnet Synchronous Motor is its synchronous operation. The rotor is equipped with high-strength permanent magnets that generate a constant magnetic field. The stator windings, when energized with a controlled alternating current, produce a rotating magnetic field. The rotor’s magnetic field locks onto and rotates in precise synchronization with this stator field. This is distinct from induction motors, where rotor current is induced, creating slip and asynchronous operation. The use of permanent magnets eliminates the need for rotor windings and the associated electrical losses, a fundamental shift in PMSM motor architecture that enables direct improvements in power density and thermal management.

Comparative Analysis: Efficiency and Power Density

When evaluated against traditional AC induction motors, the Permanent Magnet Synchronous Motor demonstrates superior efficiency. This is primarily due to the absence of rotor joule losses. In an induction motor, a portion of the input energy is expended to induce current in the rotor windings. A PMSM motor bypasses this requirement entirely. The result is a higher percentage of electrical input converted into mechanical work, particularly notable at partial load conditions common in variable-speed applications. Furthermore, the magnetic flux provided by the permanent magnets allows for a more compact design. This higher power density means a Permanent Magnet Synchronous Motor can deliver equivalent torque in a smaller frame size compared to an induction motor, optimizing machine footprint.

Precision and Dynamic Response in Motion Control

For dynamic positioning and velocity control, the performance gap widens. The synchronous operation of a PMSM motor provides a direct correlation between the applied stator frequency and rotor speed. This inherent characteristic, combined with high-resolution feedback devices, allows for exceptionally accurate speed regulation. The rotor inertia is typically lower than that of an induction motor’s squirrel-cage rotor, enabling faster acceleration and deceleration rates. The dynamic response is further enhanced by the motor’s linear torque-current relationship, which simplifies control algorithms and allows for precise torque control at very low speeds, a domain where induction motors struggle with stability and efficiency.

The transition to Permanent Magnet Synchronous Motor technology is driven by quantifiable gains in efficiency, power density, and controllability. While induction motors remain suitable for fixed-speed applications, the demands of modern, variable-speed automation for energy conservation and precision favor the PMSM motor. Our engineering at Santroll focuses on integrating these motors with matched drive technology to fully realize their potential. For applications where performance metrics directly impact throughput and operational cost, the advantages of this motor architecture provide a compelling technical and economic rationale.