A Permanent Magnet Synchronous Motor, or PMSM motor, represents a specific category of high-efficiency electric motor. We at Santroll design these motors to meet demanding performance criteria in industrial settings. Their operation differs from traditional induction motors, offering distinct advantages for applications where precision and energy savings are critical. This overview clarifies the core principles and functional benefits of the PMSM motor technology.

Core Architecture and Rotating Magnetic Field

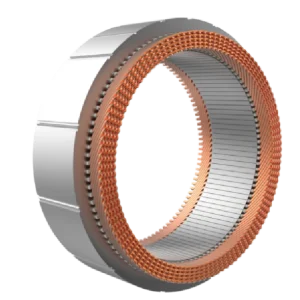

The fundamental design of a PMSM motor incorporates two main elements: a stator with windings and a rotor embedded with powerful permanent magnets. When alternating current is applied to the stator windings, it generates a rotating magnetic field. This field travels at a speed directly determined by the frequency of the power supply. The design of the stator in this type of electric motor is optimized to create a smooth, continuous magnetic rotation, which is essential for the motor’s synchronous operation and low torque ripple.

Synchronous Operation and Torque Production

The term “synchronous” defines a key characteristic. The rotor in a PMSM motor locks into and rotates at the exact same speed as the stator’s magnetic field. There is no “slip,” a phenomenon common in induction motors. The permanent magnets on the rotor create a constant magnetic field. Interaction between the rotating stator field and the fixed rotor field produces a consistent torque. This direct magnetic coupling allows the PMSM motor to maintain precise speed control and deliver high torque even at low rotational speeds, a valuable trait for many industrial processes.

Control System Integration and Performance Outcomes

Achieving the full potential of a PMSM motor requires an integrated control system. An electronic controller continuously monitors the rotor’s position and adjusts the current in the stator windings accordingly. This closed-loop control ensures optimal torque generation and operational efficiency across the motor’s entire speed range. The synergy between the motor and its controller results in high power density, meaning a compact PMSM motor can deliver significant power output. This efficiency translates directly into reduced electrical consumption and lower operational costs for the end-user.

The PMSM motor functions through a precise electromagnetic partnership between its permanent magnet rotor and the digitally controlled stator. This architecture provides a compelling combination of control accuracy, power density, and energy efficiency. For our engineering team at Santroll, the PMSM motor is a foundational technology for building advanced motion solutions. Its characteristics make it a suitable electric motor for applications where dynamic performance and operational economy are required, from automated machinery to precision control systems.