Boating technology has changed significantly over the past decade, and at Santroll, we often receive questions about how electric motors compare to traditional motors, especially regarding lifespan. For companies managing fleets or designing marine equipment, understanding these differences can directly influence operational costs and maintenance schedules.

Brushless Motor Design: Reduced Wear and Tear

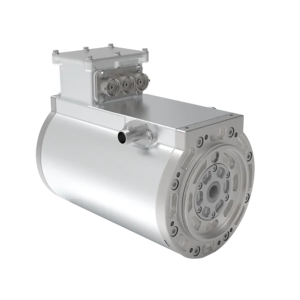

One of the most critical distinctions between PMSM (Permanent Magnet Synchronous Motors) and traditional boat motors lies in the brushless motor architecture. Traditional motors rely on brushes to transfer electrical current, which inevitably leads to friction, heat, and eventual wear. In contrast, PMSMs operate without brushes, significantly reducing mechanical degradation. We have observed in our applications that electric motors built with brushless designs maintain efficiency for a longer period, lowering downtime and maintenance interventions. This durability contributes to an extended lifespan, a vital factor for businesses aiming to reduce long-term costs and improve reliability.

Thermal Management and Efficiency

Another factor influencing motor longevity is thermal performance. Traditional boat motors generate significant heat during operation, which accelerates wear on internal components. PMSM electric motors, especially those with advanced thermal management systems, dissipate heat more effectively. At Santroll, we design brushless motors with optimized cooling pathways and high-efficiency electrical configurations. These improvements not only enhance performance but also extend operational life, allowing electric motors to sustain higher loads over time without degradation. Companies adopting PMSMs benefit from predictable maintenance schedules, reducing unexpected service interruptions.

Maintenance and Operational Lifespan

The amount of maintenance that is required is a practical measurement of the changes in longevity. When it comes to traditional motors, brushes, bearings, and other components that are prone to wear need to be inspected and replaced on a regular basis. Due to the fact that they are brushless motors, PMSMs require far less routine maintenance. Through the implementation of PMSM systems in a variety of maritime environments, we have regularly observed decreased maintenance costs and a reduction in the number of part replacements. When compared to the total cost of ownership, this reduced maintenance results in higher uptime and lower overall costs over the life of a motor. The initial purchase costs of electric brushless motors are typically outweighed by these factors, which makes electric brushless motors a feasible and long-term investment for enterprises that are searching for motor solutions.

Comparing PMSM electric motors to traditional boat motors, the difference in lifespan is tangible and impactful. Brushless motor design, enhanced thermal management, and reduced maintenance collectively extend operational life. At Santroll, we prioritize these advantages in our electric motor offerings, ensuring that marine operators experience not only efficiency but also durability. By understanding these differences, companies can make informed decisions that balance performance, reliability, and cost-effectiveness.