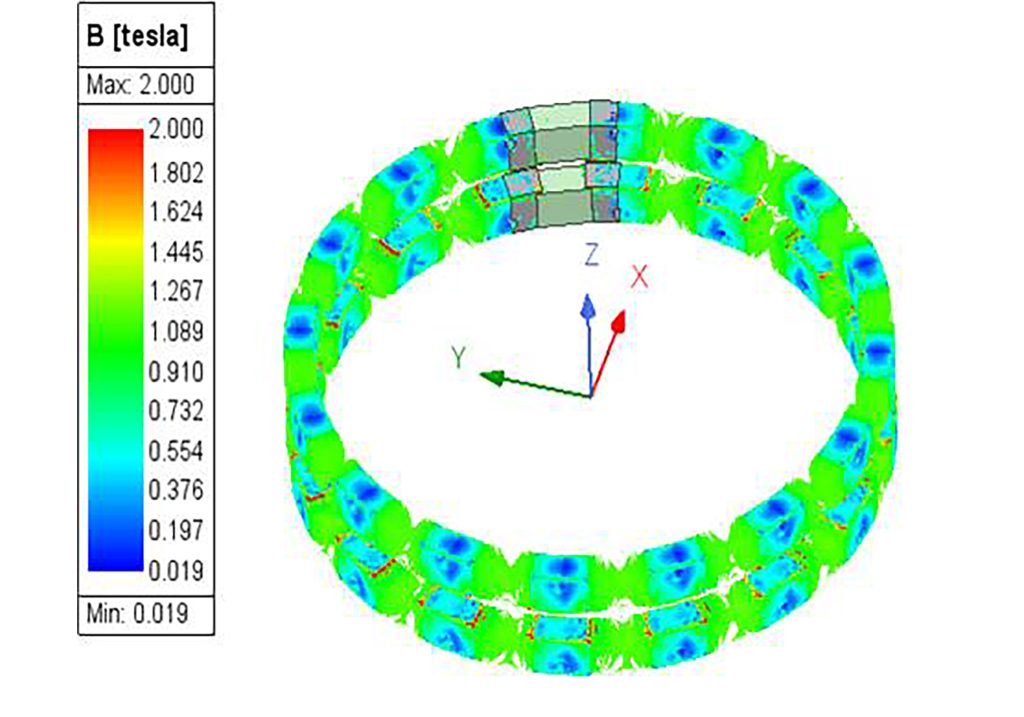

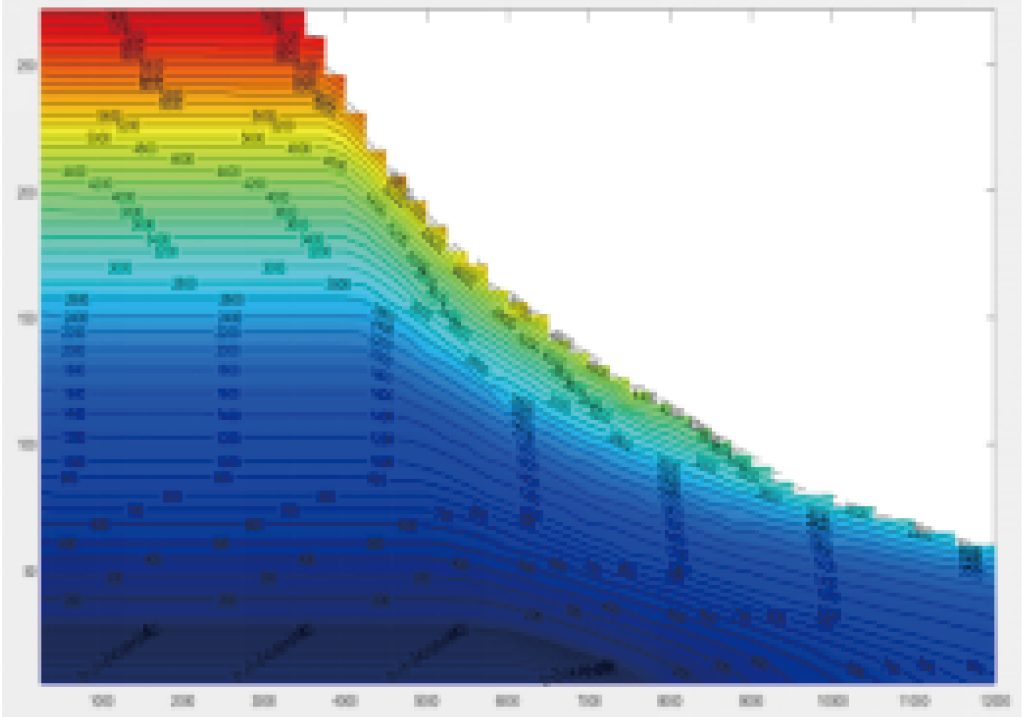

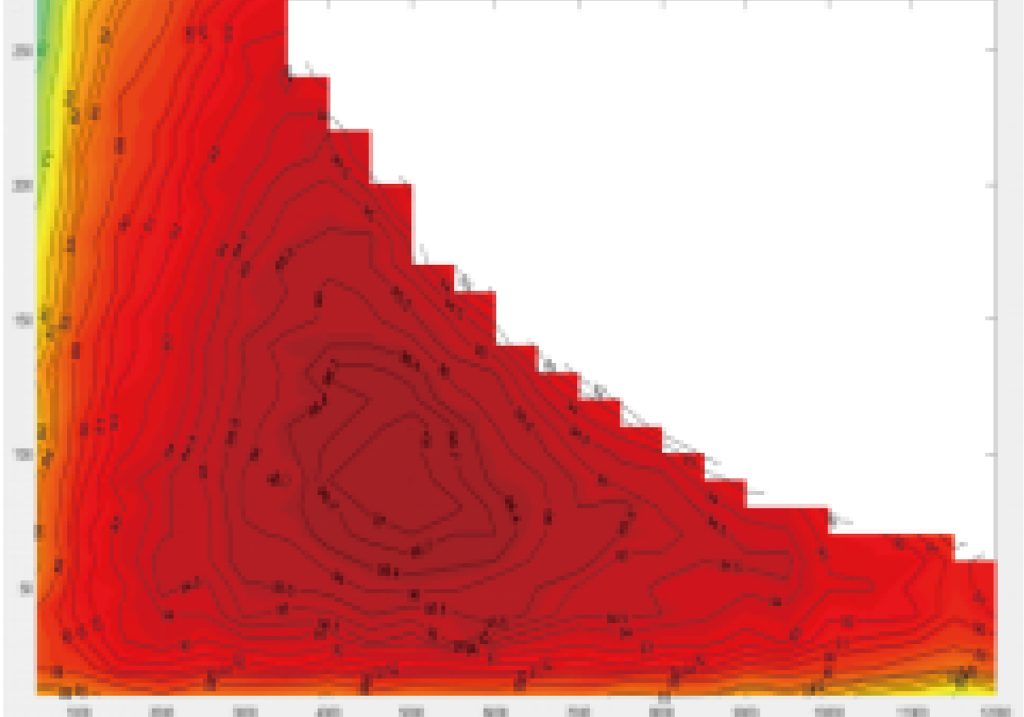

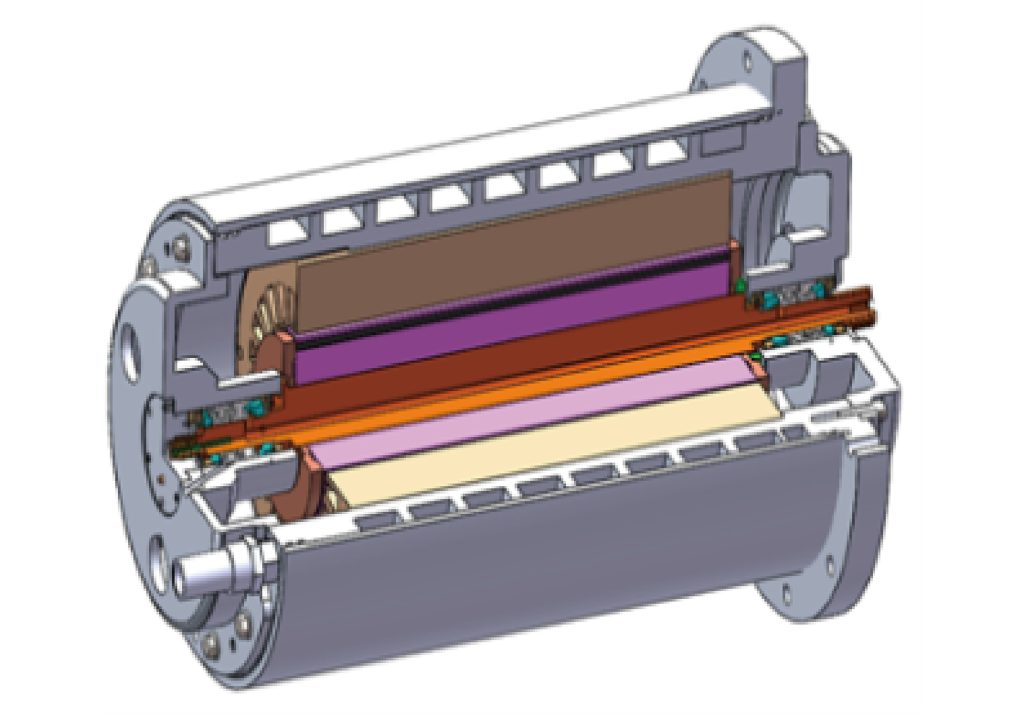

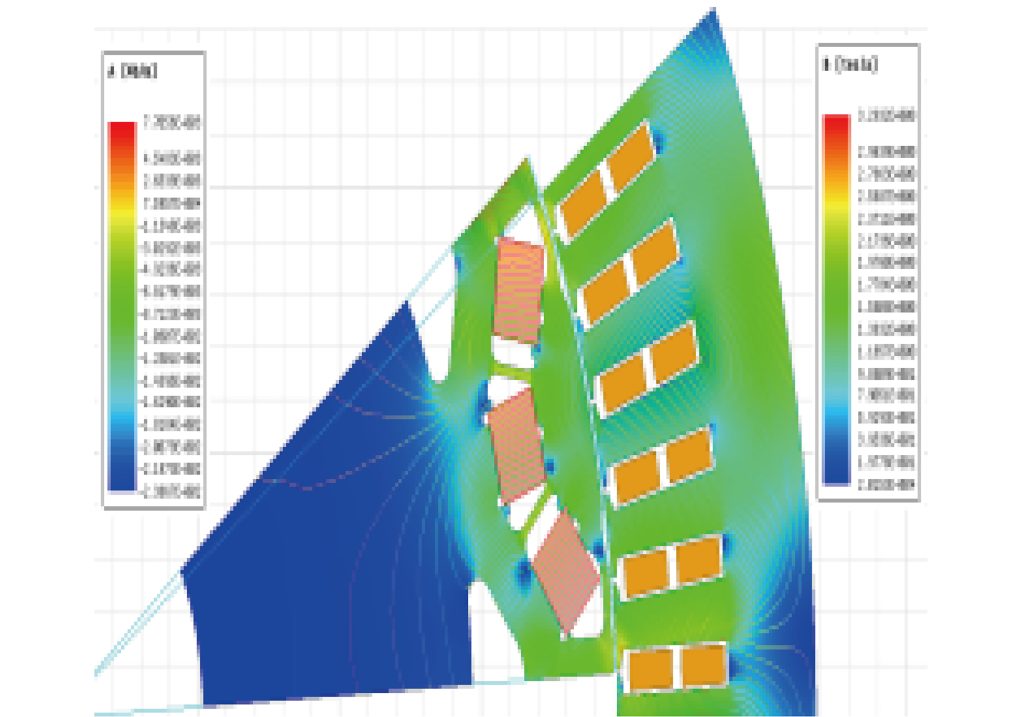

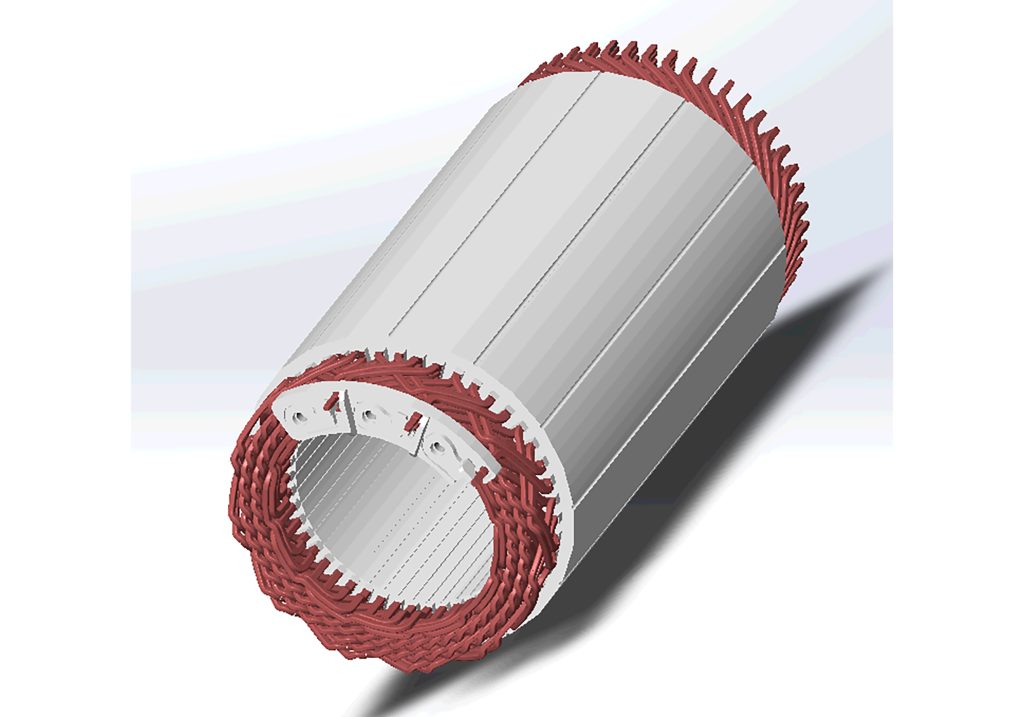

Our high power density motors feature flat wire windings for increased slot fill rate and improved power density—all in a compact form. Available in three series, they outperform traditional round wire motors in both efficiency and performance.

Santroll motor controllers are designed for precision, stability, and high compatibility across various motor types. With advanced algorithms and smart diagnostics, they ensure efficient, responsive control in electric vehicles, marine systems, drones, and industrial equipment.

Founded in 2001 as a micro-vehicle controller innovator, Santroll dominated China’s e-bike market (2003) and pioneered ultra-quiet brushless controllers (2004). Transitioning to hybrid buses (2009), it led China’s supercapacitor technology and achieved global-tier hybrid systems (2014). Shifting focus in 2017, Santroll developed cutting-edge flat wire motors—launching automated production (2020)—before its passenger car motor unit was acquired by BorgWarner for $220M (2022).

With over 700 employees and 1,233 patent applications, Santroll specializes in high power density motors and motor controllers. Our solutions power electric vehicles, ships, drones, rail systems, and more—built for performance, reliability, and customization.

Guided by the belief that “Limitless Technology Creates Unlimited Energy,” we continue to lead in the development of advanced electric drive technologies for a rapidly electrifying world.

Extreme-Environment Simulation

Turn-Key Line Solutions

To Know More about Santroll Products and Services,

Please Fill out The Contact Form.

To Know More About Santroll Products And Services,

Please Fill Out The Contact Form.

© 2024 | Santroll | Privacy Policy