An ac motor controller functions by fundamentally altering electrical power to dictate motor performance. The core task of this device is to convert fixed grid power into a variable form that precisely controls an AC induction motor’s speed and torque. We at Santroll engineer our ac motor controller products around a three-stage power conversion process, which allows for the sophisticated management of mechanical systems in industrial settings.

Stage One: Rectification of AC Power to DC

The initial phase inside an ac motor controller is rectification. The unit receives a standard AC line supply, typically 50/60 Hz, which is characterized by a sinusoidal waveform. This incoming AC power is passed through a rectifier bridge, a component composed of diodes that function as one-way valves for electrical current. This process converts the bidirectional AC voltage into a pulsating DC voltage. This raw DC power is not yet suitable for driving the motor with precision, but it establishes the foundational power reservoir for the subsequent stages. This rectification is a critical first step common to nearly every motor controller designed for AC input.

Stage Two: Filtering for a Stable DC Bus

The pulsating DC output from the rectifier requires smoothing to be useful. This is achieved by directing the power through a DC bus circuit, which employs capacitors and sometimes inductors. These components act as an electrical buffer, storing energy and releasing it to fill in the voltage gaps between the pulses. The result is a smooth, stable DC bus voltage. The integrity and capacity of this DC bus are vital for the performance of the ac motor controller, as it serves as the clean, steady power source for the final and most critical stage of the operation. This stable bus is what enables precise motor control.

Stage Three: Inversion through Pulse Width Modulation

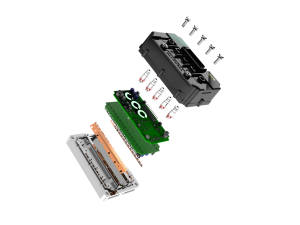

The final stage is inversion, which is the defining function of a modern ac motor controller. The smoothed DC power is fed to a set of high-speed power transistors, known as IGBTs. Using a technique called Pulse Width Modulation (PWM), the ac motor controller switches these transistors on and off thousands of times per second. By carefully controlling the sequence and duration of these pulses, the motor controller synthesizes a variable-frequency, variable-voltage AC output that mimics a sinusoidal waveform. The frequency of this synthesized waveform directly controls the motor’s synchronous speed, while the voltage is regulated to maintain optimal magnetic flux, thus providing full torque across the operating speed range.

The operational principle of an ac motor controller is a deliberate sequence of power conversion: from AC to DC, then from a stable DC bus to a precisely engineered AC output. This process grants complete command over motor speed and torque. Our design philosophy at Santroll focuses on optimizing each of these stages within our ac motor controller and broader motor controller portfolio, ensuring efficient and reliable speed control for the complex demands of industrial automation.