In the realm of precision motion control, the brushless DC motor represents a significant advancement, but its potential remains locked without its essential partner: the motor controller. We at Santroll understand that the performance of a brushless system is defined by the synergy between the motor and its electronic command center. This discussion outlines the operational principles of a brushless DC motor controller, explaining the process that transforms electrical commands into precise physical movement.

Replacing the Mechanical with the Electronic

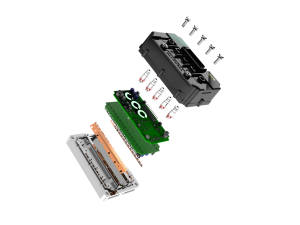

A fundamental difference between brushed and brushless DC motors is how current is delivered to the coils. Brushed motors use a physical commutation system with brushes and a commutator, which introduces friction, sparking, and wear. A brushless DC motor controller eliminates this mechanical system entirely. It functions as an electronic commutator, a high-speed switch that precisely manages power distribution. This controller is an integrated unit that dictates every aspect of the motor’s performance, from speed and torque to rotational direction. The sophistication of this motor controller directly determines the capabilities of the overall motion system.

The Core Process: Sensing, Processing, and Activating

The operation of a brushless DC motor controller is a continuous, high-speed loop. It begins with sensing. Most systems use Hall-effect sensors embedded in the motor to provide real-time data on the rotor’s magnetic pole positions. The controller’s microprocessor receives this positional feedback and executes a pre-programmed sequence. Based on the rotor’s location, the controller rapidly switches power on and off to the appropriate motor windings using a network of transistors. This sequential energization of coils creates a rotating magnetic field in the stator that pulls the permanent magnet rotor along, resulting in smooth and continuous rotation. The entire process—sensing the position, calculating the next step, and activating the correct windings—happens thousands of times per minute.

Contrasting with AC Motor Controller Functionality

While both devices manage motor function, the underlying principle of a brushless DC motor controller differs from that of a standard AC motor controller. A typical AC motor controller, or Variable Frequency Drive (VFD), works primarily by varying the frequency of the AC power supplied to an induction motor to change its speed. In contrast, a brushless DC motor controller typically works with DC power and creates a three-phase, trapezoidal or sinusoidal AC waveform. Its control is more direct, managing the commutation based on precise rotor position rather than just output frequency. This allows for superior low-speed torque, higher efficiency, and more responsive speed control compared to many VFD-driven systems, making the brushless DC motor controller a preferred solution for applications requiring dynamic performance.

The brushless DC motor controller is the intelligence behind the muscle. Its ability to perform electronic commutation provides the reliability, efficiency, and precise control that modern automation demands. This technology allows for the development of compact, powerful, and highly responsive motion systems. We integrate these advanced control principles into our designs to ensure that the performance of the motor controller meets the rigorous requirements of your applications, providing a foundation for both innovation and operational consistency.