For industrial buyers, the selection of an electric motor supplier involves evaluating more than specifications and price. A significant indicator of a supplier’s long-term reliability and product quality is its sustained investment in research and development. These financial commitments, far from being abstract overhead, translate directly into tangible advancements in the electric motor solutions provided to the market. We view R&D not as a cost, but as the foundation for delivering durable, efficient, and forward-compatible technology.

Advancing Materials and Manufacturing Techniques

A primary channel for R&D expenditure is the development of superior materials and precision manufacturing processes. A dedicated electric motor supplier invests in metallurgical research to identify alloys that reduce core losses and improve thermal tolerance. This work extends to investigating advanced insulation materials for windings that can withstand higher temperatures and voltage spikes, directly increasing motor lifespan. Furthermore, R&D funding enables the adoption of sophisticated manufacturing like automated winding and laser alignment, which minimize variations and enhance the consistency of every unit produced. These are not visible on a datasheet, but they are critical to the field reliability of the electric motor solutions you implement.

Optimizing Thermal and Electromagnetic Performance

Theoretical design only goes so far. Substantial R&D resources are allocated to computational analysis and empirical testing to refine a motor’s electromagnetic and thermal characteristics. Using finite element analysis (FEA), engineers can model magnetic flux paths to minimize losses and optimize torque density. Concurrently, computational fluid dynamics (CFD) simulations allow for the design of more efficient cooling systems. This rigorous development process, funded by R&D, results in electric motor solutions that operate cooler, run more efficiently, and deliver more power in a smaller frame size. An electric motor supplier that neglects this deep analytical work ultimately provides products based on outdated designs with inherent performance limitations.

Integrating Smart Features and System Connectivity

Modern industrial systems require more than just a rotating shaft; they demand intelligence. A forward-looking electric motor supplier directs R&D efforts toward integrating sensors, embedded diagnostics, and communication protocols. This involves developing the software and hardware necessary for condition monitoring, predictive maintenance algorithms, and seamless integration with industrial IoT platforms. These features transform a basic motor into a smart component of a comprehensive electric motor solutions ecosystem. This level of innovation is only possible through a committed investment in electronics, software engineering, and systems integration—all core R&D activities.

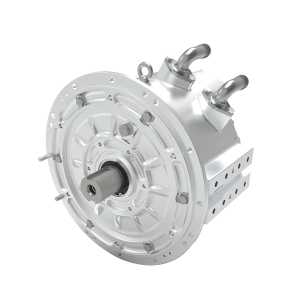

The scale and focus of an electric motor supplier’s R&D investments offer a clear window into its commitment to quality. This investment directly fuels the progression of materials science, deepens the understanding of electromagnetic and thermal dynamics, and enables the smart functionality that modern automation requires. It is a proactive effort to solve problems before they occur in your operations. At Santroll, our research and development pipeline is structured around these very principles, ensuring that the electric motor solutions we provide are not just products, but the result of a continuous dedication to engineering excellence and operational reliability for our partners.