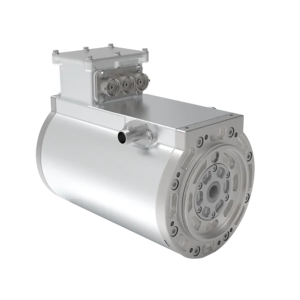

Efficiency improvements are critical in modern construction operations, and at Santroll, we continually evaluate how electric motor technology can contribute to better performance. Permanent magnet synchronous motors (PMSMs) have proven to deliver notable gains when applied to construction machinery. By focusing on features that optimize energy use and reliability, we ensure that equipment runs effectively while minimizing operational costs.

Optimized Torque for Heavy-Duty Tasks

A standout attribute of PMSMs in construction machinery is their ability to provide optimized torque under variable loads. Heavy equipment such as excavators, loaders, and cranes frequently operates under changing conditions. At Santroll, we emphasize electric motors that can maintain high torque efficiency across a wide range of speeds. This characteristic reduces energy loss, allowing machinery to perform demanding tasks without excessive power consumption. For operators, the result is smoother operation and less strain on auxiliary systems, which can also enhance the lifespan of boat motors and other electric motors in hybrid machinery setups.

Thermal Management and Continuous Operation

Construction sites often expose machinery to prolonged periods of heavy use, creating a need for effective thermal management in electric motors. At Santroll, we analyze PMSMs that incorporate advanced heat dissipation designs, ensuring stable operation even in high-load scenarios. Maintaining thermal stability allows the electric motor to operate consistently without efficiency drop-offs, which is especially important for equipment that works extended shifts. In addition, reliable cooling strategies minimize the risk of downtime and maintenance, enabling teams to keep machinery productive throughout the workday.

Durability and Reduced Maintenance

Durability is a vital consideration for construction machinery, and PMSMs excel due to their simpler mechanical design compared with traditional motors. At Santroll, we focus on electric motors that combine strong materials with robust design, reducing wear and tear during intensive operations. For boat motors and other electric motors used in hybrid construction systems, this translates into fewer service requirements and lower maintenance costs. By reducing the frequency of repairs and replacements, PMSMs contribute to overall operational efficiency and cost-effectiveness.

Integration with Equipment Control Systems

The ability to integrate PMSMs with modern control systems further enhances their value in construction applications. At Santroll, we have supported electric motors that work seamlessly with digital monitoring platforms, enabling operators to track performance metrics and schedule maintenance proactively. This integration ensures that construction machinery operates at optimal efficiency, preventing energy waste and supporting long-term reliability. For businesses managing fleets of equipment, this capability helps maximize productivity while minimizing energy and maintenance costs.

When it comes to construction machinery, Santroll knows that torque performance, temperature management, durability, and system integration are the four most important factors to consider when using PMSMs. Improved efficiency, longer machinery life, and reduced operational expenses are all benefits of electric motors built with these considerations in mind. Using electric motor technology to promote smarter, more dependable operations, businesses can increase construction productivity and sustainability by implementing these concepts.