A common consideration for Original Equipment Manufacturers is whether to pursue custom motor solutions for projects with limited volume. The perception often leans toward standard products being the only economically viable option. However, advancements in modular design and flexible manufacturing have altered this landscape. We at Santroll find that small batch custom orders are not only viable but can provide a critical competitive edge. The feasibility stems from a supplier’s ability to offer tailored performance without the traditional costs of full-scale custom tooling, enabling OEMs to differentiate their machinery and address niche applications effectively.

Adapting Standard Platforms for Application-Specific Needs

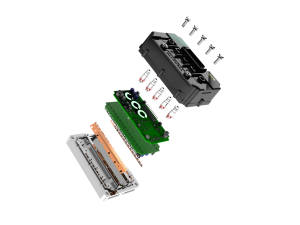

The core of modern small-batch viability lies in the intelligent adaptation of standard platforms. Instead of building a motor and controller from scratch, we utilize a modular approach. This involves modifying an existing motor frame—for instance, by integrating a specific feedback device, using a specialized winding, or applying a unique coating—and pairing it with a variable speed controller for AC motor that has been programmed with custom software parameters. This method delivers an application-specific solution while controlling costs by leveraging proven, high-volume components as the foundation. The motor controller becomes a key enabler in this customization, as its software can be tailored to create unique motion profiles that define the machine’s performance.

Addressing Low-Volume and Prototype Development Cycles

For OEMs in the prototyping or pilot production phase, the ability to source a small quantity of custom motors is invaluable. It allows for real-world testing and validation before committing to the expense of a large production order. This agility accelerates development timelines and de-risks the introduction of new equipment. A tailored variable speed controller for AC motor systems can be developed in these stages to perfect the torque response or speed regulation unique to the application. This process ensures that when the OEM is ready for full-scale production, the motor and control specification is already optimized and proven, preventing costly redesigns later.

Achieving Market Differentiation through Technical Specification

The ultimate value of a small custom batch is the creation of a machine with unique operational characteristics that competitors cannot easily replicate with off-the-shelf components. A custom-wound motor paired with a specially calibrated motor controller can achieve a specific torque-speed curve, improve efficiency at a targeted operating point, or reduce acoustic noise. This level of performance tailoring allows an OEM to build a reputation for superior technology in their market segment. The investment in a custom solution, even in small volumes, can be justified by the higher margin and enhanced market positioning the finished machine commands.

The economic model for small batch custom motor orders is firmly established through modular design and flexible manufacturing strategies. This approach allows OEMs to access specialized performance without the burden of excessive cost or lead time. The motor controller, particularly a configurable variable speed controller for AC motor systems, serves as a powerful tool in this customization process, allowing software-based differentiation to complement hardware modifications. For manufacturers aiming to introduce innovative equipment with distinct performance advantages, partnering with a supplier capable of supporting low-volume custom projects is a strategically sound decision. It transforms the motor and drive system from a commodity component into a source of proprietary value.