Industrial regulation and motor technology are increasingly intertwined. We at Santroll observe a direct correlation between tightening global emission standards and a rising preference for Permanent Magnet Synchronous Motors (PMSM). This class of brushless electric motor offers distinct advantages that align with the demands of a lower-carbon industrial landscape. The question is no longer if a shift is happening, but how quickly operations can adapt to maintain compliance and a competitive edge.

The Regulatory Pressure on Industrial Efficiency

Governments and international bodies are implementing stricter regulations to curb energy consumption and indirect emissions from industrial activity. These standards often mandate minimum efficiency levels for electric motor systems, effectively phasing out older, less efficient technologies. A standard AC induction motor, while robust, frequently operates at lower efficiency levels under partial loads, leading to significant energy waste over time. This regulatory environment creates a clear push for technologies that can deliver superior performance out-of-the-box. The brushless electric motor, particularly the PMSM type, is engineered to meet and exceed these new benchmarks, making it a strategic choice for forward-thinking operations.

PMSM Motors: A Response to Efficiency Mandates

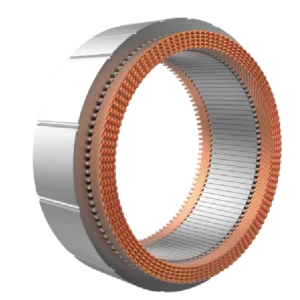

The design of a Permanent Magnet Synchronous Motor provides a direct answer to efficiency challenges. Unlike induction motors that require electrical current to create a magnetic field in the rotor, a PMSM motor uses permanent magnets to generate a constant field. This elimination of rotor electrical losses is a fundamental efficiency gain. The result is an electric motor that operates with a higher power density and superior efficiency across a wider range of speeds and loads. For businesses, this translates into reduced electricity consumption for the same mechanical output, directly lowering operational costs and helping to meet the specific metrics outlined in new emission and efficiency standards.

Application Shifts and Long-Term Operational Value

The demand for PMSM technology is most evident in sectors where efficiency and control are paramount. Industries such as automotive manufacturing (for robotic automation), HVAC (for compressor drives), and precision machining are increasingly specifying this type of brushless electric motor. The initial investment in a PMSM motor is often offset by the long-term savings in energy costs and their maintenance-free nature, as they do not have brushes that wear out. This reliability reduces downtime and contributes to more predictable lifecycle costing. Adopting a high-efficiency electric motor is not merely a procurement decision; it is an operational strategy that aligns with both economic and environmental goals.

The trajectory of industrial regulation points consistently toward greater efficiency requirements. Within this context, the functional advantages of the Permanent Magnet Synchronous Motor position it as a key technology for compliance and performance. We see the adoption of PMSM systems as a logical step in the evolution of industrial drive systems. Integrating this caliber of brushless electric motor into new equipment and retrofit projects prepares a business for both the regulatory demands of the present and the competitive pressures of the future.